power 832 dsc manual

DSC Power832 Manual: A Comprehensive Guide (Updated 12/04/2025)

This comprehensive guide details the installation, wiring, and programming of the DSC Power832/PC5010 alarm panel, offering insights into keypad functions and security code management.

It covers zone definitions, system programming options like entry/exit delays, and communicator setup using SIA protocols.

Furthermore, it explains PGM output configuration, troubleshooting common issues, and utilizing programming worksheets for efficient system customization.

The DSC Power832 is a robust and versatile security control panel, forming the core of a comprehensive intrusion detection system. This panel, often paired with the PC5010, offers a scalable solution for residential and commercial applications.

It supports a wide range of sensors and keypads, providing flexible configuration options to meet specific security needs. Understanding its capabilities is crucial for effective installation and programming.

This manual will guide you through the process of setting up, programming, and maintaining your Power832 system, ensuring optimal performance and reliability; It’s designed for both installers and end-users seeking a deeper understanding of their security infrastructure.

Understanding the Power832 Control Panel

The DSC Power832 control panel serves as the central processing unit for your security system, managing all connected sensors, keypads, and communicators. It features a modular design, allowing for expansion and customization.

Key components include the CPU board, power supply, and backup battery, ensuring continuous operation even during power outages. The panel’s programming is primarily done through the keypad, utilizing a specific code sequence.

Understanding the panel’s layout and functionality is essential for effective troubleshooting and system maintenance, enabling quick responses to alarms and system faults.

Keypad Functionality and Navigation

The Power832 keypad provides the primary interface for controlling and interacting with the security system. Key functions include arming and disarming the system, entering user codes, and accessing system information.

Navigation typically involves using numeric keys and function keys, such as the “Enter” and “Exit” buttons. Programming functions are accessed by entering the master code followed by specific command sequences.

Familiarizing yourself with the keypad layout and button functions is crucial for efficient system operation and responding to alerts.

Master Code and User Codes

The DSC Power832 utilizes a hierarchical security code system, featuring a Master Code and multiple User Codes. The Master Code grants full access to all system programming functions and settings, requiring careful protection.

User Codes, assigned to individual users, allow for arming and disarming the system without compromising overall security. To program a new user, the Master Code is required, followed by a two-digit user number.

Regularly changing the Master Code is recommended to maintain system integrity.

Programming New User Codes

To add a new user to the DSC Power832 system, initiate the programming sequence by entering the Master Code. Subsequently, press the ‘5’ key to access the user code programming function.

Next, input the desired two-digit user number (e.g., 06) for the new user. The system will then prompt you to enter a four-digit personal identification number (PIN) for that user.

Confirm the PIN, and the new user code will be successfully programmed.

Changing the Master Code

Altering the Master Code on your DSC Power832 system is crucial for maintaining security. Begin by entering your current Master Code. Then, access the Master Code change function – typically initiated through a specific sequence on the keypad.

The system will prompt you to enter a new four-digit Master Code, followed by a confirmation entry to verify accuracy.

Ensure the new code is memorable yet secure, and avoid easily guessable combinations. Successful completion will update the system’s primary access code.

Zone Programming

Zone programming defines how the Power832 interprets signals from connected sensors. Each zone represents a specific area or device, like a door, window, or motion detector. Proper configuration is vital for accurate alarm triggering and system responsiveness.

This involves assigning zone definitions and types – instant, delay, or no entry – based on the area’s characteristics.

Utilizing programming worksheets (PC5010 Zone 1-16 Assignment) streamlines this process, ensuring each sensor is correctly mapped to its designated zone within the system.

Zone Definitions and Types

Zone definitions categorize sensor inputs, dictating how the Power832 reacts to activations. Common types include ‘instant’ zones, triggering immediate alarms – ideal for glass breaks. ‘Delay’ zones, like entryways, allow a grace period for disarming. ‘No Entry’ zones activate alarms if disturbed during arming.

Understanding these distinctions is crucial for tailoring the system to specific security needs.

Correctly assigning zone types minimizes false alarms and ensures reliable protection, enhancing the overall effectiveness of the Power832 security system.

Assigning Zones to Sensors

Properly assigning zones to sensors is fundamental for accurate alarm system operation. Using the keypad, navigate to the programming section and select zone programming mode. Each sensor requires a unique zone number, corresponding to its physical location and defined type.

Carefully consider the sensor’s purpose when assigning its zone.

Incorrect assignments can lead to misinterpreted alarms or system malfunctions. Refer to the programming worksheets for a clear overview of zone assignments and ensure accurate configuration for optimal security.

System Programming Options

The DSC Power832 offers extensive system programming options for tailored security. Key settings include adjusting entry and exit delay times, customizing alarm responses, and configuring system features like instant or entry delay alarm types.

These options are accessed through the keypad programming menu, requiring the master security code for authorization.

Careful consideration of these settings is crucial for optimizing system performance and minimizing false alarms, ensuring a reliable and effective security solution.

Entry Delay Configuration

The entry delay allows a designated timeframe to disarm the system upon zone activation. Configuring this delay is vital to prevent unwanted alarms during legitimate entry.

The Power832 allows customization of entry delay times for individual zones or globally, accessed via keypad programming using the master code.

Appropriate settings depend on the property layout and user needs, balancing convenience with security. Shorter delays enhance security, while longer delays offer greater usability.

Exit Delay Configuration

The exit delay provides a timeframe for users to leave the premises after arming the system, preventing false alarms triggered during departure. This setting is crucial for system functionality.

The DSC Power832 allows for customizable exit delay durations, adjustable through keypad programming with the master code. Different zones can have unique exit delay settings.

Proper configuration ensures sufficient time for a safe exit, while minimizing potential security vulnerabilities. Consider user habits and property size when setting the exit delay duration.

Communicator Programming

Communicator programming on the DSC Power832 enables alarm signal transmission to a central monitoring station, ensuring rapid response in emergency situations. This process involves wiring uplink communicators correctly.

The system supports various communication protocols, notably the SIA protocol, requiring specific configuration settings for compatibility with monitoring services. Accurate programming is vital for reliable communication.

Proper setup includes defining account numbers and communication formats, ensuring the central station receives clear and actionable alarm data. Refer to the programming manual for detailed instructions.

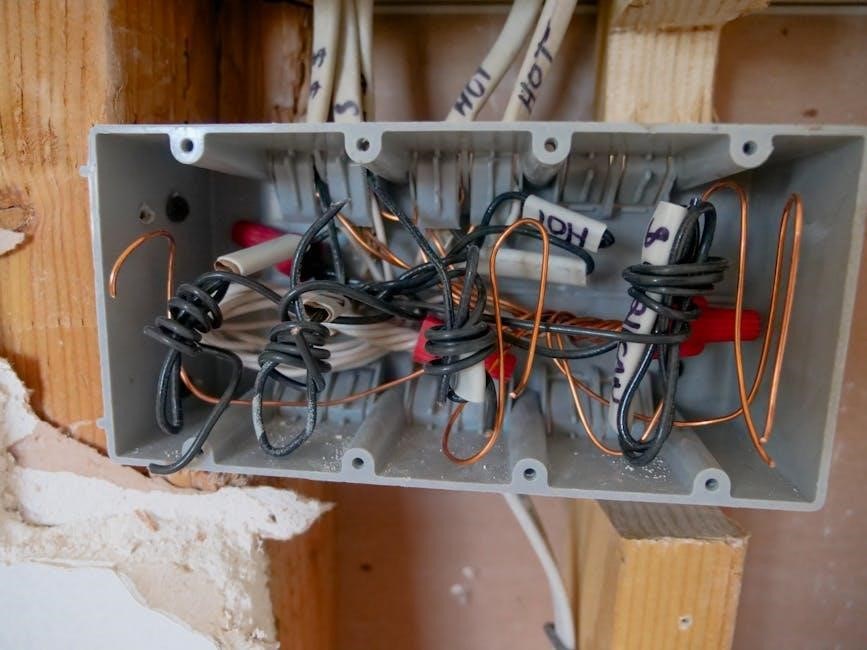

Wiring Uplink Communicators

Wiring uplink communicators to the DSC Power832 requires careful attention to terminal assignments and polarity. Typically, these communicators connect to the control panel’s dedicated communication terminals, often labeled for telephone line connections.

Ensure proper grounding and secure connections to prevent signal interference. The wiring diagram in the installation manual provides a visual guide for correct installation.

Verify compatibility between the communicator and the Power832 before wiring, and always disconnect power during the installation process for safety.

SIA Protocol Configuration

Configuring the SIA (Security Industry Association) protocol on the DSC Power832 is crucial for reliable communication with central monitoring stations. This involves programming the panel to transmit alarm signals in the standardized SIA format.

Access the system programming menu and navigate to the communicator settings. Select the appropriate SIA protocol version supported by your monitoring center.

Verify the account number and signal format settings are accurate to ensure proper event reporting. Refer to the DSC programming manual for detailed instructions and specific code entries.

PGM Output Programming

Programmable General Purpose Outputs (PGM) on the DSC Power832 offer versatile control over external devices. These outputs can be activated by specific alarm events or system states, enhancing system functionality.

Access the PGM programming menu to define the activation conditions and output behavior. New output types, like ‘Sensor Reset’, allow for power cycling of latching sensors.

Configure PGM outputs for relays to control sirens, strobe lights, or door strikes. Careful planning and programming are essential for optimal PGM output utilization.

New PGM Output Types (Sensor Reset)

The DSC Power832 introduces a valuable new PGM output type: Sensor Reset. This function specifically addresses latching sensors, which remain in a triggered state until manually reset.

By assigning the ‘Sensor Reset’ PGM output, the system can automatically power cycle the sensor upon a defined event, such as alarm verification or system arming.

This eliminates the need for manual sensor resets, improving system responsiveness and reducing false alarm occurrences. Proper wiring and programming are crucial for effective sensor reset functionality.

Configuring PGM Outputs for Relays

PGM outputs on the DSC Power832 can be effectively utilized to control external relays, expanding system functionality. When configuring for relay operation, ensure the relay’s coil voltage matches the PGM output’s specifications.

Proper wiring is essential, connecting the PGM output to the relay coil and providing a common ground. Programming involves defining the trigger conditions for the PGM output, activating the relay accordingly.

Relays can then control devices like sirens, strobe lights, or door strikes, enhancing security and automation capabilities.

Troubleshooting Common Issues

Addressing issues promptly ensures optimal system performance. Common problems include low battery warnings, indicating a need for battery replacement to maintain backup power. Communication failures can stem from wiring issues or incorrect communicator programming.

Verify wiring connections and SIA protocol settings. Zone faults often point to sensor problems or incorrect zone definitions. Refer to the programming manual for specific error codes and troubleshooting steps.

System resets can resolve minor glitches, but persistent issues require professional assistance.

Low Battery Warnings

A low battery warning signifies the backup battery is nearing the end of its lifespan, potentially compromising system functionality during power outages. The Power832 will typically display a “Low Battery” trouble signal on the keypad.

Immediate battery replacement is crucial to ensure uninterrupted security. Use only batteries specified in the manual to avoid damage. After replacement, the system may require a reset to clear the warning.

Regular battery checks are recommended as preventative maintenance.

Communication Failures

Communication failures indicate a problem with the panel’s ability to connect with the central monitoring station. This could stem from a disconnected phone line, a faulty communicator, or network issues. The keypad will display a “Comm Failure” or similar trouble signal.

Verify phone line connectivity and communicator wiring first. Consult your monitoring company to confirm account status and signal reception.

Troubleshooting may involve SIA protocol checks and communicator reprogramming.

Programming Worksheets Overview

DSC Power832 programming worksheets streamline system configuration. These worksheets, like the PC5010 versions, provide a structured method for zone assignments and system settings. They detail each zone’s purpose and sensor type, ensuring accurate programming.

Utilizing these worksheets minimizes errors and simplifies the process. French language versions are also available for bilingual installations.

Effective use requires understanding zone definitions and system options, facilitating a customized security solution.

PC5010 Zone 1-16 Assignment

The PC5010 Zone 1-16 assignment worksheet is crucial for defining each zone’s function within the DSC Power832 system. This worksheet details the specific sensor type connected to each zone, such as door, window, or motion detector.

Accurate assignment ensures proper alarm triggering and reporting. Carefully documenting each zone’s purpose is essential for effective troubleshooting and future modifications.

Properly completed worksheets are vital for a reliable and customized security setup.

Using Programming Worksheets Effectively

Programming worksheets, like the PC5010 versions, streamline the configuration of your DSC Power832 system. Before making changes to the panel, meticulously fill out the worksheet with desired settings for each zone and system function.

This pre-planning minimizes errors and simplifies the programming process.

Always retain a copy of completed worksheets for future reference and troubleshooting. Utilizing these tools ensures a well-documented and efficiently programmed security system.

Advanced Programming Features

The DSC Power832 offers sophisticated features beyond basic setup. Event log review provides a detailed history of system activity, aiding in diagnostics and security analysis.

Remote access setup, when configured correctly, allows for system control and monitoring from a distance.

Understanding communicator reporting codes (SIA protocol) is crucial for reliable alarm transmission. These advanced options enhance system functionality and provide greater control over your security infrastructure.

Event Log Review

The DSC Power832’s event log is a powerful diagnostic tool, recording a chronological history of system events. This includes alarms, troubles, user access, and system programming changes.

Reviewing the log helps identify patterns, troubleshoot issues, and verify system integrity.

Accessing the log requires the master code and navigating through the keypad menu. Understanding event codes is essential for accurate interpretation and effective security management. Regular log review is a proactive security measure.

Remote Access Setup

Enabling remote access for your DSC Power832 system allows control and monitoring via smartphone or computer. This typically involves connecting a compatible communicator module, like a VoIP or cellular module, to the panel.

Configuration requires programming the communicator with your service provider’s details.

Once set up, you can arm/disarm the system, view event logs, and receive notifications remotely. Ensure secure credentials and follow the provider’s instructions for optimal performance and security.

Security Codes Management

Effective security code management is crucial for system integrity. The DSC Power832 utilizes a Master Code for full system access and individual User Codes for authorized users.

Programming new users requires entering the Master Code followed by a unique two-digit number.

Regularly changing the Master Code is recommended to prevent unauthorized access. Avoid easily guessable codes and maintain a record of all active User Codes for accountability and system security.

Master Security Code Procedures

The Master Security Code grants complete control over the DSC Power832 system. To initiate programming functions, including user code management and system settings, entering this code is essential.

Protecting this code is paramount; avoid using easily discernible numbers or patterns.

Regularly changing the Master Code enhances security. If compromised, immediately reprogram it to prevent unauthorized access and maintain the integrity of your security system. Document the new code securely.

Communicator Reporting Codes

DSC Power832 systems utilize specific reporting codes when communicating with central monitoring stations. These codes detail event types, such as alarms, troubles, or system status updates.

Understanding these codes is crucial for accurate monitoring and efficient response.

Refer to the programming manual (section 5.7) for a comprehensive list of codes and their corresponding meanings. Proper configuration ensures the monitoring station receives clear and concise information regarding system activity.

Understanding Reporting Codes

DSC Power832 reporting codes are vital for clear communication with central stations. Each code represents a specific event – alarm, trouble, or system status.

Codes are typically three or four digits long, conveying detailed information about the zone and event type.

Accurate interpretation of these codes by the monitoring center ensures appropriate dispatch and response. Refer to the detailed code list within the programming manual for precise definitions and troubleshooting guidance.

Power Supply and Backup Battery

The DSC Power832 requires a stable power source for reliable operation. Typically, it utilizes a 16.5 VAC power supply, ensuring consistent performance.

A backup battery is crucial for maintaining system functionality during power outages.

Regularly check the battery’s charge level and replace it according to the manufacturer’s recommendations – usually every 3-5 years. Proper battery maintenance safeguards against false alarms and system failures, ensuring continuous security.

Power Requirements

The DSC Power832 control panel generally operates on a 16.5 VAC, 60Hz power supply. It’s essential to verify your local voltage matches this specification before installation.

The system also requires a 12VDC, 7Ah sealed lead-acid battery for backup power during outages.

Ensure the power supply has sufficient capacity to handle all connected devices, including keypads, sensors, and communicators, to prevent operational issues and maintain system reliability.

Battery Replacement Procedures

When replacing the 12VDC backup battery, always disconnect the AC power supply first to avoid electrical shock.

Carefully disconnect the old battery and connect the new, fully charged 7Ah sealed lead-acid battery, observing correct polarity.

Allow the system approximately 24 hours to fully charge the new battery and restore normal operation. Record the date of battery replacement for future maintenance tracking and ensure proper disposal of the old battery.

Installation Considerations

Proper installation is crucial for optimal system performance. Mount the DSC Power832 control panel in a secure, concealed location, away from extreme temperatures and moisture.

Ensure adequate ventilation and follow all local electrical codes during wiring. Use appropriate gauge wiring for all connections and secure all cables to prevent tampering.

Refer to the detailed wiring diagrams provided in this manual for correct connections and consider professional installation for complex setups.

Basic Installation Guidelines

Begin by mounting the Power832 control panel securely, ensuring easy access for maintenance. Connect the power supply, observing correct polarity, and install a backup battery for uninterrupted operation.

Wire zone inputs according to the zone definitions, utilizing appropriate resistors for end-of-line supervision.

Connect the keypad(s) and communicator, verifying proper communication signals. Thoroughly test all zones and system functions after installation, referencing the programming manual for detailed procedures.

Wiring Diagrams

Detailed wiring diagrams illustrate connections for the Power832 control panel, keypads, and various sensors. These diagrams showcase proper wiring for normally open (NO) and normally closed (NC) zones, ensuring accurate alarm signaling.

Specific diagrams cover uplink communicator wiring, including connections for SIA protocol compatibility.

PGM output wiring is also illustrated, demonstrating connections for relay activation and sensor reset functionality. Always refer to these diagrams during installation to guarantee correct and secure wiring practices.

PC5010 Compatibility

The DSC Power832 exhibits full compatibility with the PC5010 alarm panel, enabling seamless integration and expanded functionality. PC5010 v2.0 programming worksheets are available for detailed system configuration.

These worksheets facilitate zone assignments, system options, and communicator settings, mirroring the Power832’s capabilities.

Users can leverage the PC5010’s advanced features alongside the Power832’s robust control, creating a highly customizable and reliable security solution. French language programming resources are also accessible for PC5010 users.

PC5010 v2.0 Programming Worksheets

The PC5010 v2.0 programming worksheets are essential tools for configuring the DSC Power832 system when utilizing the PC5010 panel. These worksheets provide a structured approach to zone assignments, defining each zone’s purpose and sensor type.

They also detail system options, including entry and exit delays, and communicator settings for reliable alarm reporting.

Available in both English and French, these worksheets streamline the programming process, ensuring accurate and efficient system setup for optimal security performance.

French Language Programming Resources

For users requiring French language support, DSC provides dedicated programming manuals and worksheets for the Power832 system. These resources offer a complete translation of the installation and programming guides, ensuring accessibility for French-speaking installers and end-users.

Specifically, PC5010 v2.0 programming worksheets are available in French, facilitating configuration in a familiar language.

Accessing these resources simplifies system setup and troubleshooting, promoting wider adoption and effective utilization of the PowerSeries 8-32 zone control panel;

Accessing French Programming Manuals

French programming manuals for the DSC Power832 and PC5010 can be directly accessed through the DSC website’s comprehensive documentation section. Look for the “PowerSeries 8-32” product page and navigate to the downloads area.

There, you’ll find PC5010 v2.0 programming worksheets specifically labeled as “French” versions.

Alternatively, contacting DSC support can provide direct links to these resources, ensuring you have the latest translated documentation for efficient system programming and installation.

Resources and Support

For extensive documentation and support regarding the DSC Power832, the official DSC website is the primary resource. It offers downloadable manuals, programming guides, and technical specifications for both the Power832 and compatible PC5010 panels.

Direct contact with DSC support is available through their website, providing assistance with troubleshooting, programming questions, and warranty inquiries.

Additionally, online forums and communities dedicated to security systems often contain valuable user-shared knowledge and solutions related to the Power832.

DSC Website and Documentation

The DSC website serves as a central hub for all Power832 documentation, including comprehensive manuals and programming worksheets. Users can access detailed guides for installation, wiring, and system configuration, specifically tailored for the PowerSeries 8-32 zone control panel.

Downloadable resources encompass PC5010 compatibility information, including v2;0 programming worksheets, and even French language programming manuals for broader accessibility.

The site provides up-to-date product pages and technical bulletins, ensuring users have the latest information for their Power832 system.

Contacting DSC Support

For personalized assistance with your DSC Power832 system, direct contact with DSC Support is readily available. Their knowledgeable team can address specific programming questions, troubleshoot complex issues, and provide guidance on wiring and installation challenges.

DSC support can clarify details found within the comprehensive manuals and programming worksheets, ensuring optimal system performance.

Accessing their support channels offers a valuable resource for resolving any difficulties encountered during the setup or maintenance of your Power832 security system.